The sphere of production has been significantly transformed by the proliferation of innovative technology in recent years. Among the wealth of disruptive technologies that have emerged, the role of CAD (Computer-Aided Design) drafting has been pivotal in revamping the quality of product manufacturing in a wide range of industries. Throughout this post, we will delve into the mechanisms through which CAD drafting can be harnessed to substantially improve quality control in production.

Table of Contents

Understanding the Power of CAD Drafting

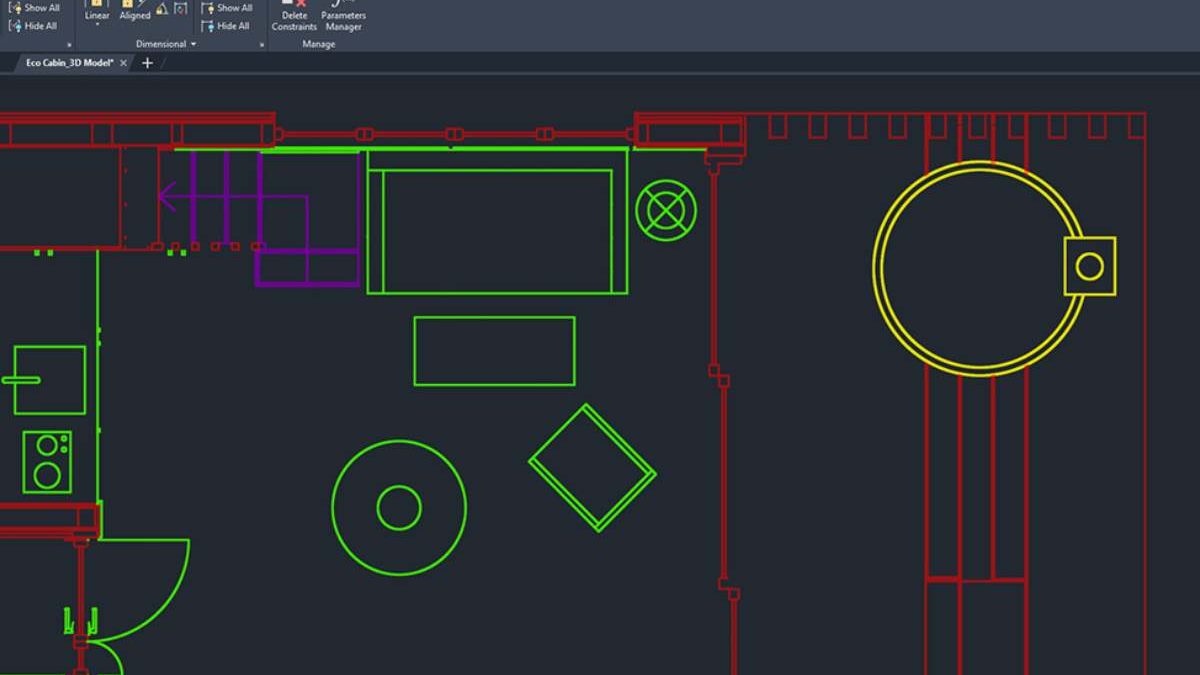

At the forefront of innovative design and production, CAD drafting is a transformative tool. It encompasses computer technology’s capacity for creating, modifying, analyzing, and refining a design, expediting the journey towards a higher quality and more efficient product.

CAD Drafting: The Gateway to Precision in Design

CAD drafting gives industries the power to create designs that are supremely accurate and reliable. The technology provides an incredibly high level of precision that is virtually impossible to reach through traditional, manual drafting methods – opening the door to unparalleled product specifications.

Streamlining the Process of Design Revisions

Another undeniable advantage of CAD drafting technology is the ease with which it allows for modifications to designs. The flexibility of the software means that any flaws detected in the primary design phases can be rectified efficiently and seamlessly, ensuring that the workflow remains unbroken.

Tracing the Impact of CAD Drafting on Quality Control

The utilization of CAD Drafting has brought forth measurable improvements in managing quality permanence across a broad range of products.

Distilling Consistency in Production

Consistency in production is a holy grail that manufacturers have been chasing. CAD drafting makes this dream a reality by enabling a finely-detailed overview of every design aspect, thus minimizing the chance of errors and ensuring higher quality and uniformity across all produced articles.

Minimizing Pitfalls: Error Mitigation through CAD Drafting

A key attribute of CAD software is its ability to identify potential inconsistencies and issues within a draft. This feature is instrumental in reducing errors, which subsequently results in an uplift in the final product’s overall quality.

By integrating elite cad drafting services, firms can create designs that adhere to meticulous specifications. This not only ensures superior quality standards, but also enhances overall productivity and profitability.

Unearthing the Multitude of Benefits from CAD Drafting in Production

The powerful influence of CAD drafting is articulated in an impressive array of advantages it delivers to the manufacturing sector. Each benefit has transformative potential in its own right, collectively promising a paradigm shift in production processes.

Bolstering Efficiency and Productivity

CAD drafting serves as a significant catalyst in streamlining the design, prototyping, and manufacturing process. It essentially refines the entire production pipeline. The improved speed and accuracy unleash a new level of efficiency, eliminating unnecessary delays and redundant processes. This accelerated pace, combined with precision, elevates productivity to unprecedented levels. Fewer errors and quicker turnaround times inherently mean that more high-quality products can reach the market faster.

Smoothing the Path to Collaboration

One of the lesser-known yet crucial advantages of CAD drafting is how it nurtures collaboration. The digital nature of CAD files enables effortless sharing amongst team members, regardless of their geographic locations. This accessibility ushers in a new era of collaboration, fostering a productive exchange of ideas and creativity.

Trimming Production Costs

Let’s not forget the tremendous impact of CAD drafting on production costs. Technology ushers in a future where production errors are drastically reduced. This significant decrease in errors directly correlates with a reduction in waste. By eliminating the drain of resources into flawed products, the production process becomes leaner, saving considerable costs. For any company, tangible cost savings without compromising quality control are a highly desirable advantage.

Implementing competent autocad drafting services into the production process not only ensures cost-efficient output but also contributes to enhancing the overall operational efficiency of firms. These comprehensive services act as a robust backbone, supporting the demanding production pipeline and helping businesses stay competitive in a rapidly evolving industrial landscape.

Conclusion

The integration of CAD drafting into a production process is undoubtedly a strategic game-changer in the industry. Its ability to enable improved efficiency, precise designs, and significant cost savings make it a non-negotiable asset for a production process that aspires to enhanced quality control. As we observe the increasing recognition of CAD drafting’s transformational capabilities, it is clear that we can anticipate wider adoption and application across global industry sectors. By capitalizing on technology-driven drafting services, industries can gear up for lucrative breakthroughs in their quality control processes.